- Company

- Products

- Brands

- Imada

- Koken

- Kanon

- Tohnichi

- Cedar

- BIX

- Niigata Seiki

- Imada Seisakusho

- Universal Testing Machine – Imada Seisakusho

- Special Attachments

- Special Specification Testing Machine

- Torque Tester

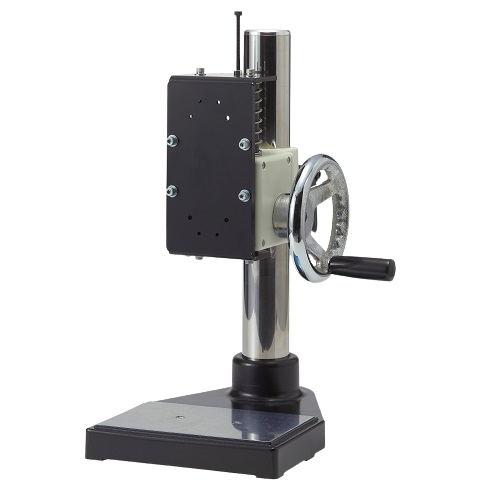

- Push Pull Stand – Imada Seisakusho

- Packing Compression Testing Machine – Imada Seisakusho

- High Speed Peeling Testing Machine – Imada Seisakusho

- Flexure Testing Machine – Imada Seisakusho

- Spiral Spring Durability Testing Machine – Imada Seisakusho

- Leather Testing Equipment & Machine – Imada Seisakusho

- Lamp Socket Pull & Insert Testing Machine – Imada Seisakusho

- Crash Testing | Seat Belt Collision Testing – Imada Seisakusho

- Spring Testing Machine – Imada Seisakusho

- Gedore

- Iijima Electronics

- Otsuka

- Industry

- Automobile

- Airline

- Chemicals / Raw Materials

- Cosmetics / FMCG

- Construction / Furniture

- Electronics / Semiconductors

- Energy

- Ergonomics / Sporting Goods

- Food & Beverages

- Industry Machinery / Parts

- Jewelry & Watch

- Musical Instruments

- Occupational Training

- Packaging / Containers / Paper

- Pharmaceutical & Medical Equipment

- Textile & Clothing

- Toy & Nursery

- Intraocular Lens (IOL)

- Services

- Contact