Will you borrow someone’s toothbrush? No Right. Then why borrow a Torque Wrench from some other mechanic? There’s an unspoken etiquette in many shops about not borrowing someone else’s torque wrench without asking.

It’s so important? Let’s understand why.

The right Torque Wrench ensures uniformity in tightening all fasteners to the same specification, which is crucial for reliability. This is especially important in applications requiring consistent torque force. Using the wrong or improperly calibrated torque wrench can lead to over-tightening or under-tightening, causing damage or creating stress points. Over-tightening can strip threads or damage parts, while under-tightening can lead to loose or failing components. A properly calibrated torque wrench helps avoid these problems.

Understanding Torque Wrenches

A torque wrench is a specialized tool used to apply a specific amount of torque to a fastener, such as a nut or bolt. It ensures that the fastener is tightened to the proper specification, which is crucial for the safety, performance, and reliability of mechanical systems. Torque wrenches typically have a ratchet mechanism for turning the fastener and a calibrated scale to set the desired torque value. When the set torque is reached, the wrench usually makes a clicking sound or has a visual indicator.

Click Torque Wrench: The most common type, it produces a clicking sound when the preset torque is achieved.

Beam Torque Wrench: Uses a scale and a pointer to indicate the amount of torque being applied.

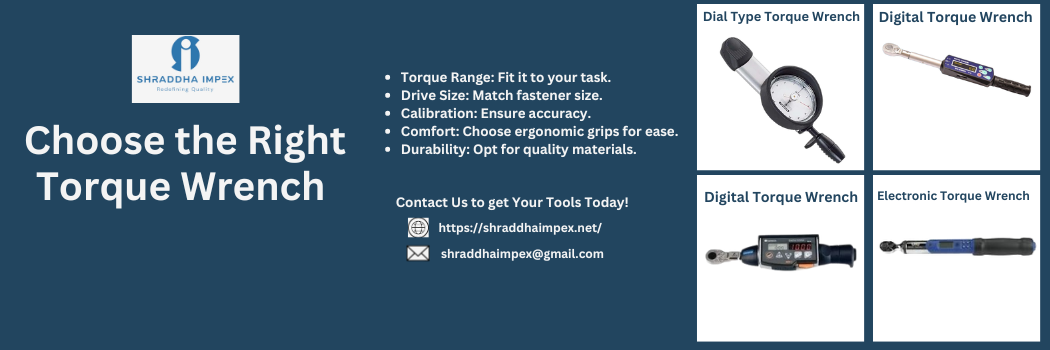

Dial Torque Wrench: Has a dial gauge to show the exact torque value, allowing for more precise adjustments.

Digital/Electronic Torque Wrench: Features a digital display for setting and reading the torque value, often with additional features like data storage.

Now let’s talk about its applications and where all its used or can be used

Automotive Repair:

Engine Assembly: Ensures bolts and nuts on engine parts are tightened to specifications for optimal performance.

Wheel Lug Nuts: Properly torques lug nuts to prevent wheel detachment and ensure vehicle safety.

Suspension: Tightens suspension components to maintain proper alignment and performance.

Industrial Machinery:

Assembly Lines: Maintains quality control by ensuring machinery parts are precisely tightened.

Heavy Equipment: Secures components on machinery like cranes and bulldozers for safe operation.

Precision Equipment: Used in aerospace and electronics for exact tightening of sensitive components.

Construction:

Structural Steel: Ensures bolts in steel structures are tightened to maintain safety and integrity.

Pipe Fittings: Secures flanges and fittings in pipelines to prevent leaks.

Concrete Formwork: Tightens formwork and rebar connections for accurate concrete structures.

General Maintenance:

Household Repairs: Tightens screws and bolts in furniture and fixtures to ensure stability.

DIY Projects: Provides correct tightness for various projects, enhancing durability.

Aerospace and Aviation:

Aircraft Assembly: Ensures precise tightening of fasteners in aircraft for safety and performance.

Medical Equipment:

Assembly and Calibration: Guarantees accurate tightening of medical devices for reliability and accuracy.

Factors to Consider When Choosing a Torque Wrench

Selecting the right torque wrench involves considering several key factors to ensure precision and durability. Here’s a concise guide to help you make an informed choice.

Accuracy and Calibration

Accuracy is crucial for a torque wrench, as it ensures fasteners are tightened to exact specifications. Regular calibration is essential to maintain this accuracy over time. A well-calibrated wrench prevents mechanical failures and ensures reliable performance.

Torque Range

Selecting a torque wrench with the appropriate torque range is crucial for its effectiveness. Torque wrenches come in various ranges, typically from low (e.g., 10-100 ft-nm) to high (e.g., 100-600 ft-nm). It’s important to choose a wrench that covers the range of torque values needed for your specific tasks. Using a wrench that is too high or too low for the job can lead to inaccuracies and potential damage to components. Ensure that the selected torque wrench can handle the minimum and maximum torque values required for your applications.

Build Quality and Durability

Opt for a torque wrench made from high-quality materials like hardened steel or aluminum alloys. A robust build enhances durability and reliability, reducing the likelihood of breakage and maintaining performance over time.

Ease of Use

User-friendly features, such as a clear scale, ergonomic grip, and audible or tactile feedback, improve the ease of use. These features help you set and achieve the correct torque accurately and comfortably.

Price vs. Quality

While cheaper options may be tempting, investing in a higher-quality torque wrench often proves beneficial. Look for a balance between cost and quality that suits your needs, ensuring accuracy and durability without overspending.

Detailed Comparison of Different Torque Wrench Types

Beam Torque Wrench

Pros:

Simplicity: Easy to understand and use, with a straightforward scale and pointer.

Durability: Typically robust and less prone to failure compared to other types.

Cons:

Less Precision: Not as precise as other types, particularly for finer torque settings.

Reading Difficulty: Requires careful reading of the scale, which can be challenging in low light or tight spaces.

Best Use Cases:

Ideal for general-purpose applications where high precision is less critical.

Useful for beginners due to its simplicity and low cost.

Click Torque Wrench

Pros:

Accuracy: Provides precise torque settings with an audible click when the desired torque is reached.

Ease of Use: User-friendly, with built-in feedback mechanisms to prevent over-tightening.

Cons:

Calibration Needs: Requires regular calibration to maintain accuracy.

Cost: Generally more expensive than beam wrenches.

Best Use Cases:

Excellent for automotive repair and assembly tasks requiring exact torque specifications.

Suitable for professional use due to its reliability and ease of use.

Pros:

Precision: Offers highly accurate torque readings with digital displays.

Features: Often includes programmable settings, data storage, and customizable alerts.

Cons:

Battery Dependence: Requires batteries or charging, which can be inconvenient.

Cost: Typically more expensive due to advanced features.

Best Use Cases:

Ideal for high-precision tasks in aerospace, electronics, and advanced automotive work.

Useful in environments where digital readouts and advanced features are beneficial.

Dial Torque Wrench

Pros:

Accuracy: Provides precise torque measurements with a clear dial gauge.

Readability: Easy to read the torque value directly from the dial.

Cons:

Bulkiness: Can be bulkier and less convenient to handle compared to other types.

Calibration: Requires regular calibration to ensure accuracy.

Best Use Cases:

Best suited for precision work where accurate readings are essential.

Commonly used in industrial applications where detailed torque measurement is required.

To know more about different types, read here

Maintenance and Care Tips

Proper Storage

Storage Environment: Store your torque wrench in a protective case to prevent physical damage. Keep it in a cool, dry place to avoid exposure to moisture and extreme temperatures.

Avoid Over-Tightening: When not in use, set the torque wrench to its lowest setting to prevent internal spring tension from affecting accuracy.

Regular Calibration

Importance: Regular calibration ensures that the torque wrench maintains its accuracy over time. Without proper calibration, the tool’s readings can become unreliable, leading to potential mechanical issues.

Frequency: Calibration should be performed periodically according to the manufacturer’s recommendations, or after heavy use. For high-precision tasks, more frequent calibration may be necessary.

Cleaning and Handling

Cleaning: Wipe down the torque wrench with a clean, dry cloth after use to remove any dirt or debris. Avoid using harsh chemicals or solvents that could damage the tool.

Handling: Handle the torque wrench with care to avoid dropping or mishandling, which can impact its accuracy. Always use the tool according to the manufacturer’s instructions to ensure longevity.

Recommended Brands & Models

Top Brands

Gedore: Known for its superior craftsmanship and innovative tool solutions, Gedore is a premier choice for professionals seeking reliability and performance in industrial applications

Norbar: Known for its precision engineering and robust construction, Norbar is a trusted choice for professionals seeking accuracy and reliability in torque control for industrial applications.

Best Models for Different Needs

Selecting the right torque wrench involves considering its type, maintenance requirements, and reputable brands. By choosing a tool that matches your needs and following proper care guidelines, you can ensure reliable performance and long-lasting accuracy.

1. QLK – Adjustable, Ratchet Torque Wrenches

2. GLK- Adjustable, Ratchet Torque Wrenches with rubber grip

3. BLK – Adjustable by Hex Wrench, Ratchet Torque Wrenches with rubber grip

4. QSPK – Pre-Set, Ratchet Torque Wrenches, Metal Handle

5. SPCK – Pre-Set, Replaceable Head Torque Wrenches

Lets Recap!

Borrowing a torque wrench might seem like a minor issue, but using the right tool is crucial for precision and reliability. Just as you wouldn’t borrow someone’s toothbrush, you shouldn’t borrow a torque wrench without proper consideration. The correct torque wrench ensures that all fasteners are tightened uniformly to the required specifications, which is vital for mechanical integrity. Using an improper or poorly calibrated wrench can result in over-tightening or under-tightening, leading to damage or failure of components.

A torque wrench is designed to apply a specific amount of torque to a fastener, ensuring it is tightened to the correct specification. There are several types of torque wrenches, including Click Torque Wrench, Beam Torque Wrench, Dial Torque Wrench, Digital Torque Wrench.

Each type has its pros and cons and is suited for specific applications. Maintenance is crucial for keeping a torque wrench accurate and reliable. Proper storage, regular calibration, and careful cleaning and handling extend the tool’s lifespan.

Reputable brands like Tohnichi, Kanon, and Cedar, offer high-quality options for various needs. Choosing the right torque wrench involves balancing accuracy, build quality, ease of use, and cost. By selecting a suitable model and adhering to maintenance best practices, you can ensure effective and precise performance in your mechanical tasks.